ABOUT US

WelcomeTo Our Company

SPINT FILTER IN A MANUFACTURER OF PERFORMANCE AIR FILTERS AND SPECIAL INTAKES SINCE 1952. IS THE OLDEST COMPANY IN THE WORLD THAT MANUFACTURES SPECIAL AIR FILTERS.

Established in 1952, Sprint Filter began production of innovative, high-performance air filters and intake systems, working together with the best manufacturers of supply systems and top teams.

Constant research and development of new filtering fabrics and intake systems have been at the heart of Sprint Filter products for over 60 years.

Thanks to this experience, Sprint Filter can meet all types of requirements; from a simple performance filter replacing the OEM unit, to entire intake systems utilizing carbon fiber, fiberglass and plastics.

Filtering elements manufactured from unique microcalibrated polyester fabrics are incorporated into every Sprint Filter design. In 2010, Sprint Filter started to modernize its production plants and launched its motorcycle line.

Today, Sprint Filter is the trusted supplier to over 70% of the MotoGP teams, as well as OEM supplier to several models of Ducati Super Sport motorcycles.

Sprint Filter is actually one of the leading supplier in the World Touring Car Cup (WTCR) and National TCR series.

In the 2019 Sprint Filter is the technical supplier of all Honda Civic Type-R WTCR and all Honda Civic Type-R TCR builded by Jas Motorsport, of all Alfa Romeo Giulietta Veloce WTCR and of all the Alfa Romeo Giulietta Veloce TCR builded by Romeo Ferraris and of another leading WTCR car builder brand.

In the last five years, Sprint Filter models P08, P037, P08F1-85 have become the benchmark for the aftermarket and racing industries.

In October 2018, Sprint Filter restructured its automotive air filter and intake production to in crease their product offerings to supply most of the vehicles on the road today

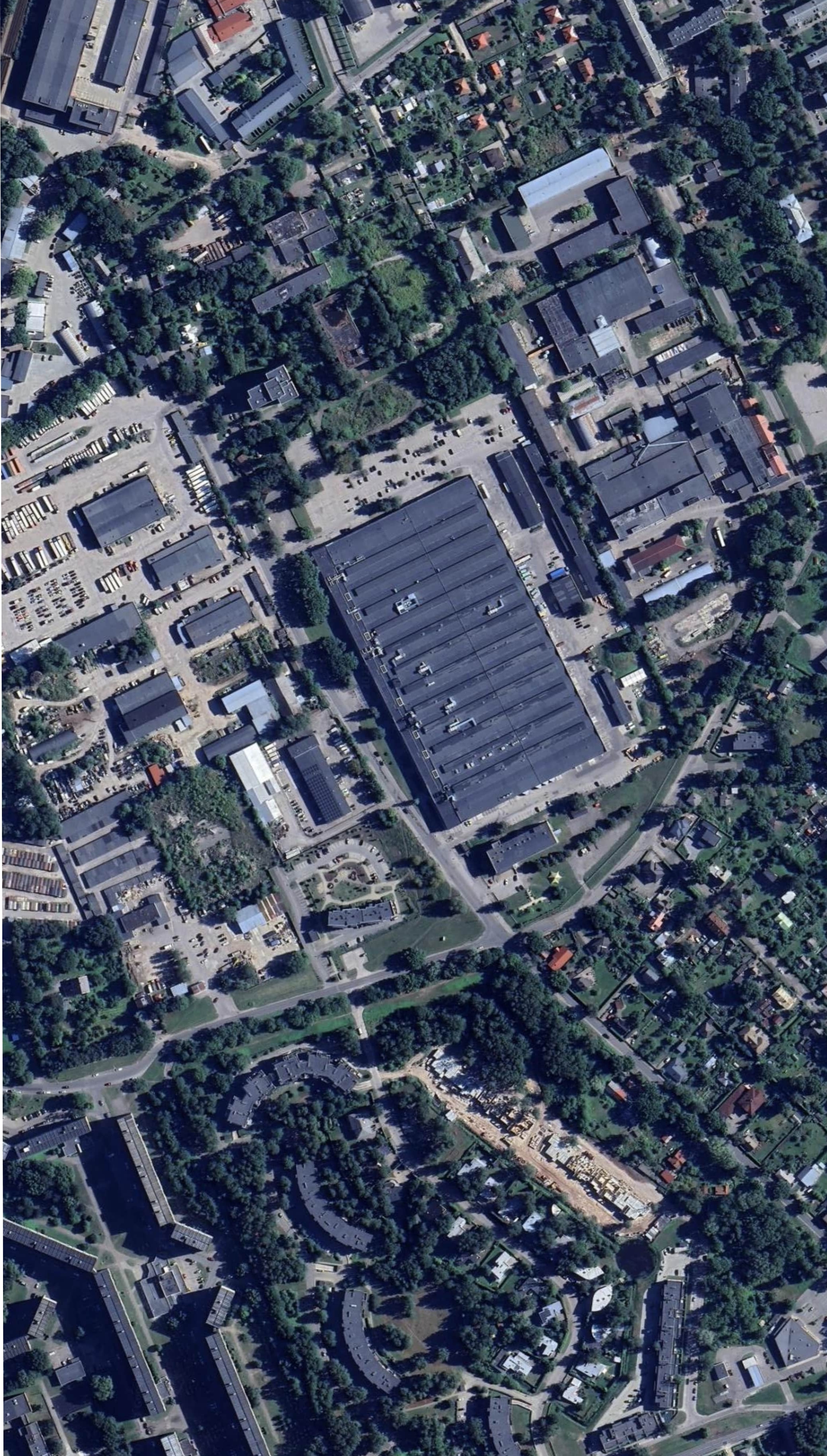

In the new manufacturing Latvian facility we have incrased the machineries and the daily production. A new Research O Development Dept. Has been created with the ultimate tecnological tools available for manufacturing and testing new products